DETAILS

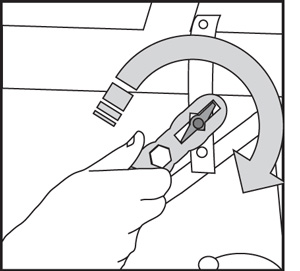

Sometimes wingnuts and associated clamps just need to be a little bit tighter, shackle pins need to come undone without resorting to bashing it on the nearest solid item and there is never a bottle opener to hand in catering. With this in mind, we worked with the people manufacturing clamps to come up with this tried and tested tool. The Original Wingnut Spanner!

Founded in 2003 the design was finalised and has remained the same throughout, its form most definitely follows its function and we are proud to see its worldwide acceptance and popularity remain.

The slim profile ensures it sits well in your pocket with steel thick enough that we have yet to see one break or deform given normal tasks, although we have certainly seen them used for abnormal tasks too.

Please ensure you are using the correct clamp or fitting for the task at hand and remember that being very tight doesn’t make it very safe! The primary task the spanner was designed for came about through the daily outrigging of Source 4 profiles and molefays / blinders from touring trusses. Using half couplers ensures that the trusses are not damaged but they needed a touch more torque to stop the focus from slipping mid-show.

With the addition of M10 and M12 cutouts, the fixture can also be tightened down to stop further wayward movement. Secondly, the spanner has a narrow slot to enable the easy movement of cam clamps as found in most moving lights flying hardware. Although simple enough in principle these are all too commonly overly tight and consequently, people will use the nearest available source to give it the all-important quarter-turn – hence jagged edges and bent metalwork making for costly repairs and injured technicians

Wingnut Spanner Images

Shipping

Bulk Orders

Payments

Shipping

Delivery costs are available when you check out, wingnut spanners are usually dispatched within 48 Hours of ordering. Orders are sent using the Royal Mail ‘Large letter service’.

For deliveries outside the UK orders are sent using Royal Mail ‘International Standard Service’ with the postage cost calculated according to your region.

Bulk Orders

Please contact us for quantities in excess of 5 wingnut spanners or for trade enquiries.

Payments

Payment can be simply made using a credit / debit card with stripe. We also take ApplePay and GooglePay.

The payment are in your local currency in most European countries and selected destinations worldwide.